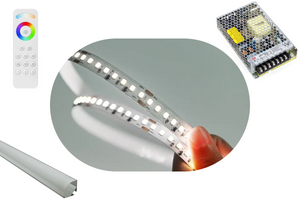

In modern lighting, LED strips play an important role, providing endless possibilities for creating an unforgettable atmosphere in any room or street. LED strips, available in large quantities thanks to their sophisticated technology, allow you to create bright lighting and a variety of effects. The most common types of glow are COB and SMD, each of which has its own features and advantages. Let's take a closer look at these two types of LED strip lights and their uses.

SMD LED strips

SMD (Surface Mount Device) LED strips are one of the most popular and effective lighting solutions on the market today. Their popularity is determined by the many benefits they offer.

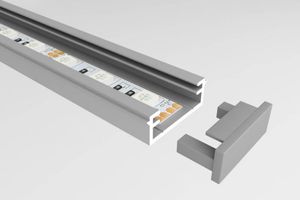

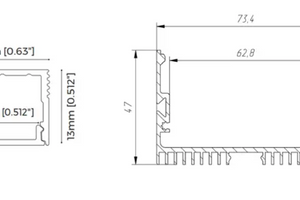

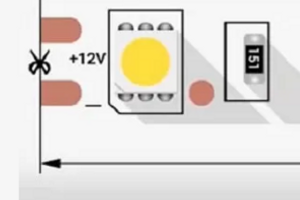

First of all, SMD technology allows manufacturers to place LEDs directly on the surface of the strip, making them smaller and more flexible. This allows the use of SMD tapes in areas of various sizes and shapes, including indoor and outdoor lighting, interior decoration and urban infrastructure.

The second important advantage is their high efficiency and low energy consumption. SMD LEDs consume significantly less electricity than traditional light sources, resulting in significant savings in utility bills and emissions.

In addition, SMD tapes have excellent glow quality, which allows you to achieve a variety of color and lighting effects. They are also known for their durability and reliability, making them an ideal choice for long-term use.

Overall, SMD LED strips are recognized as a major innovation in the lighting industry, offering efficiency, reliability and endless possibilities in lighting and decoration.

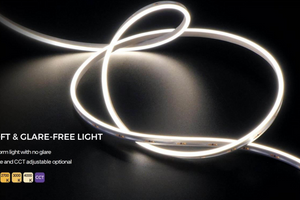

COB LED strips

COB (Chip on Board) LED strips are an innovative lighting technology that impresses with its quality and intensity of glow. In this technology, LED elements are located on a special substrate, which allows for a much larger, powerful glow on a single strip.

One of the key advantages of COB tapes is their high brightness. This technology allows you to achieve significantly higher levels of illumination than most other types of LED strips. This is especially useful when lighting large spaces or in situations where intense light is needed.

In addition to high brightness, COB tapes are also famous for their uniform glow. Chip on Board technology ensures even light distribution, avoiding the "spot" glow effect that can be characteristic of other types of LED sources.

The efficiency of COB tapes is especially important. They consume less energy than traditional light sources and have a long service life, which reduces energy supply and maintenance costs.

As a result, COB LED strips impress with their high quality, high brightness and reliability, making them an ideal choice for a variety of lighting applications, from indoor lighting to automotive use and many other applications.

Energy efficiency:

One of the main characteristics of COB and SMD LED strips is high energy efficiency. COB tapes are renowned for their high performance and production efficiency, making them an ideal choice for lighting applications. However, it is important to note that both types of LEDs are also highly energy efficient compared to conventional incandescent bulbs. The efficiency of both depends on the lumens used, with more lumens leading to improved efficiency.

Color and color temperature:

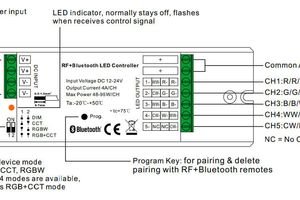

In terms of color and color temperature, SMD tapes seem to be advantageous. They provide a greater range of colors and allow for greater color temperature control. Using RGB primary colors, SMDs can create virtually any color and flexibly change color temperature. In contrast, COB LED has a limited ability to express color and color temperature, emitting only one color. However, this may be intended for stable lighting.

Light quality:

Regarding the quality of light, both types of LED strips differ due to the difference in the number of diodes. SMD strips, which typically have more diodes, can produce light with flare, making them ideal for spot lighting. COBs, on the other hand, produce uniform illumination without glare, and their light beam can be easily changed.

Production Cost:

In terms of manufacturing cost, SMD tapes typically cost more due to the use of more materials. Compared to COB, which consumes less materials, it can result in 5% less production costs. However, these are general estimates and costs may vary depending on the manufacturer and the specific product.

Brightness:

LEDs, in general, produce brighter light, making them different from regular incandescent bulbs. However, there is a difference in brightness among COB and SMD due to the difference in the number of lumens. COB strips typically have at least 80 lumens per watt, while for SMD this can range from 50 to 100 lumens per watt, making COB lighter and more powerful.

Manufacturing process:

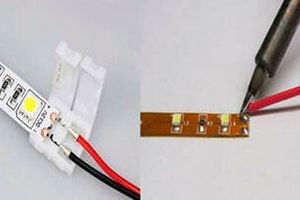

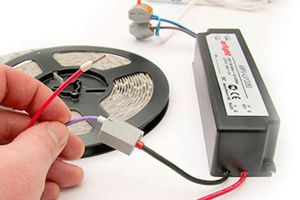

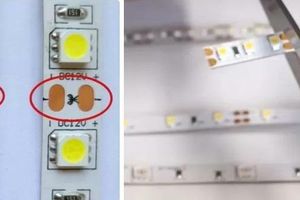

Both types of LED strips differ in their production processes. SMD tapes use insulating adhesive and conductive adhesive to attach the chips, they are welded and then coated with epoxy resin after performance testing. In COB, the chips are attached directly to the PCB and are also coated with epoxy resin after testing the efficiency.

Application:

COB and SMD tapes are used in various industries. SMDs are ideal for lighting commercial facilities, clubs, restaurants, and shops. WITH

on the other hand, COB technology is applied in various industrial and security applications. The COB light beam makes it ideal for light coating.

Before choosing between COB and SMD, it is important to consider all of these factors and determine which type of LED strip lights best suits your needs and specific applications.

At Artled you will find a wide range of different LED strips to suit your lighting needs. We pride ourselves on offering you a selection of high quality products and are always ready to provide professional support and advice. Whatever your projects or ideas, we are ready to help you find the perfect LED strip lights that suit your needs and budget. Visit our Artled store and give us the opportunity to make your lighting bright and effective!