Have you decided to use LED strips for your next project, or are you almost ready to put it all together? If you have many series of LED strips, and you want to connect them to the same power supply, you may be wondering whether they should be connected in series or in parallel.

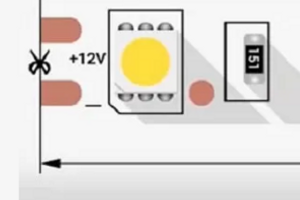

If you just need to connect one LED segment to the corresponding power supply wires of the same color, the LED strips come with markings that indicate which side to connect the positive and which side – negative (ground) wire. If you have two or more sections of LED strips and don't know how to connect them, keep reading to find out if you should connect your LED strips 'in series'. Or “parallel”!

Note: From an electrical point of view, the name “serial” and “parallel” actually wrong! We use these terms in this text for simplicity, but we enclose them in quotation marks for precision. Please see the conclusion of the article for a more detailed explanation.

Serial and parallel connection of LED strips

How to connect LED strips “in series”

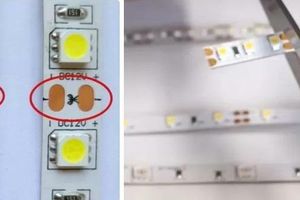

The idea of connecting two LED strips “in series” is probably the most obvious and simple approach. Think of it as connecting one end of an LED strip to the other. If you just need to go a short distance, solderless connections can be useful, or you can run longer distances with copper wires cut to length. Watch for voltage dips on long runs, but otherwise all you need to do is connect the positive/negative copper pins of one part of the LED strip to the positive/negative copper pins of the other.

This is a quick and easy approach as it does not require a separate wired connection to the power source. You simply allow a “jump” between two sections of the LED strip.

The disadvantage is that this increases the chance of voltage drops, resulting in lower luminous flux among the LEDs furthest from the power source. The reason for this is that the connection of LED strips “in series” allows electric current to flow in only one direction. The first few inches of an LED strip installation must pass all electrical current to the entire installation, which can function as a bottleneck for current flow, reducing the voltage and current reaching further sections of the LED strip.

How to connect light strips “in parallel”

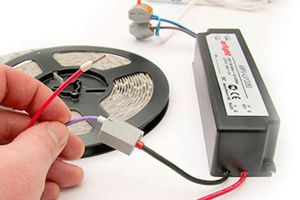

An alternative to connecting several sections of LED strips is a “parallel” connection. This method involves the creation of independent lines or sections of the LED strip, each of which is connected directly to the power source.

Since they are connected directly to the power supply, this reduces the amount of current that must pass through any segment of the LED strip. This can significantly reduce the risk of voltage drops.

The biggest downside to this strategy is that it will require a bit of extra wiring. The main problem is that most power supplies only have one of each positive and negative output wire, so connecting more than one section of LED strip will require splitting that output across multiple wires.

Special disconnect terminals are available for this purpose.

Another problem is that some parts of the LED strip can be located at a great distance from the power source. Long wires can not only be an additional expense in these cases, but they must also be of appropriate gauge. Otherwise, the loss of voltage in the cables may occur before you even reach the LED strip part.

What is the best way to connect LED strips?

Connecting LED strips in “parallel” is the best option for several reasons. In this method, each section of the LED strip is connected directly to the power source, forming separate power lines. This helps to significantly reduce the amount of current that must pass through each segment of the LED strip.

The main advantage of a parallel connection is the avoidance of significant voltage losses. When LED strips are connected in “series”, the voltage can drop due to the initial sections carrying all the electrical power for the whole installation, resulting in a loss of brightness in the remote sections.

In a parallel connection, this disadvantage is reduced, since each section has its own power line, which allows maintaining a stable voltage throughout the installation. This is especially important when using longer tapes or with many sections.

Therefore, for optimal brightness and stability of LED strips, it is recommended to use a parallel connection.