If you are faced with the task of which LED strip is best suited for your project, then you should sort out this issue even before ordering on the site. In addition to other parameters described in the article “LED Tape, Where and How to Cut Correctly?”, Today I would like to dwell in more detail on the supply voltage, namely, on 12 Volt and 24 Volt tape.

It will be useful for people with basic knowledge of electricians and electronics to find out how different-voltage diode tapes differ. Why, in some cases, a less powerful backlight tape is sufficient, while in others, 24 V is indispensable.

LED strip, comparing the 2 most popular options

There are several internal parameters that affect not so much the technical as the aesthetic indicators of your future lighting, these are:

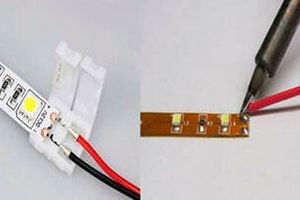

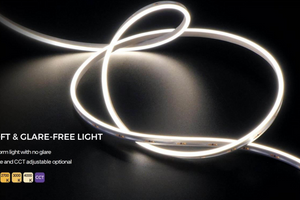

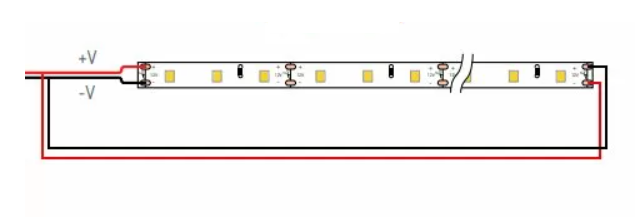

1. Brightness. Despite the widespread belief that there is no difference in brightness between the 12 and 24 volt tape, the less powerful one still shows some decrease in luminescence towards its end. At first, it glows brighter and gradually fades away. The reason is a small voltage drop across the printed track. To correct this nuance, you can supply power at the same time to the beginning and end of the diode strip. Do not forget about the observance of polarity: “plus to plus”, “minus to minus”. In this embodiment, it will shine with the same brightness along its entire length. 24 volt LED tape - does not have such a drawback.

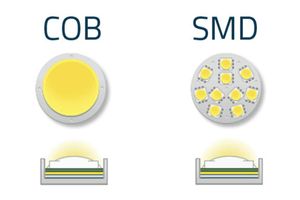

2. LED type. We would like to draw your attention to the fact that the brightness of each tape depends on 3 indicators:

- LED type (SMD2835, SMD3014, SMD3838, etc.)

- density of luminaire diodes per 1 linear meter (from 30 pcs/m to 256 pcs/m)

- manufacturer (Rishang, COLORS, ESTAR).

Particular attention should be paid to the last parameter, since there are a lot of fakes on the electronic equipment market, including LED products of world brands. Therefore, the LED ice strip purchased from trusted companies will already be much better, more durable and of higher quality.

3. Consumption current. According to this parameter of the tape, 24 volt has more advantages. The indicator of the current consumed in it is two times less than that of its 12 volt counterpart. This means that the voltage loss across the conductors will also be less. Moreover, the current-conducting tracks on the tape itself heat up less, which, logically, prolongs its service life. For 24 V tape lighting, a smaller wire is used, so the installation itself is simplified, and the project becomes more attractive in price.

4. The number of diode lamps per 1 linear meter. According to this indicator, LED tape of different power does not differ at all, since in each of these modifications, you can choose the required number of diodes. At the manufacturer - it can be from 30 to 256 pieces per 1 linear meter for both tapes.

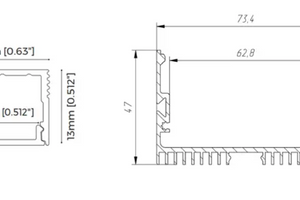

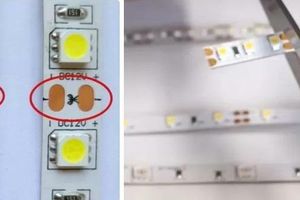

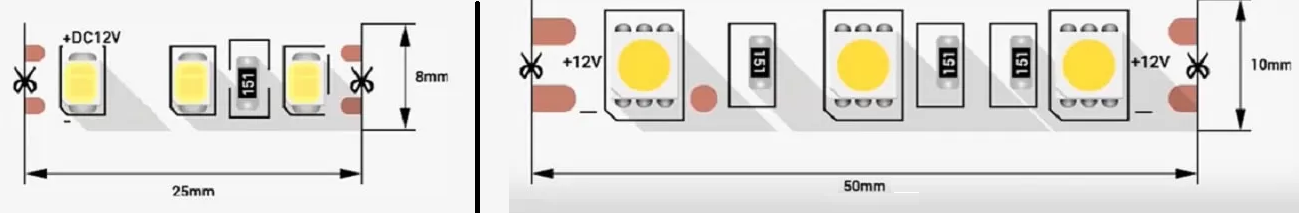

5. Cut multiplicity. The optimal distance between the cut lines for different tapes is different. This indicator directly depends on the previous one - the density of diodes per meter, and with average indicators for each tape, they are minimally:

- from 3 pieces - at 12 volt;

- from 6 pieces - at 24 volt.

If to create a general illumination of the ceiling, the cutting step is not so important, then for local areas (for example, in niches) it will be a very useful indicator.

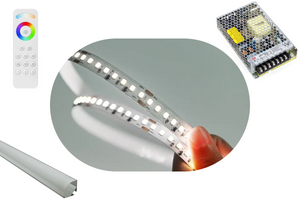

LED strip 12 V and 24 V, its power supply and control

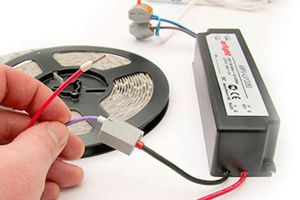

The correct, and most importantly, thoughtful connection of the LED strip is a real opportunity to save on your project, moreover, not due to the quality of the elements, but only due to reasonably selected devices:

- power unit. If you carefully calculate the rated voltage and choose an adapter that matches the tasks, the LED strip, colored or white, will not only not burn out, but will also work for the longest possible time under “comfortable” conditions for it. If you find it difficult to make the right choice of power supply, it is better to use the help of our consultants. This will save you not only time and money, but also the tape;

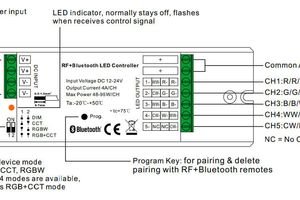

- amplifier/controller/dimmer. What to do if the LED strip is more powerful than 180W? With the 12 volt version, an additional installation of an amplifier will be required, while with the 24 volt version, one dimer will be enough. The absence of an additional amplifier reduces the cost of backlighting. A dimmer, if present in the system, provides maximum operating range on a 24 volt strip that is twice as long as a 12 volt strip. The same thing happens with controllers. Colored 24 V LED tape will require fewer of these devices for mounting long sections.

Conclusion: from the point of view of efficiency, for a standard backlight, the choice is obvious. Despite the fact that a 24 Volt LED tape is more expensive than a 12 Volt one, it is more profitable with a further selection of the remaining elements of the system. Therefore, it wins in terms of its consumer characteristics. Whereas, a 12-volt tape can be used to illuminate objects that have an appropriate power supply system (12 V) implemented. These are, for example, cars and yachts.