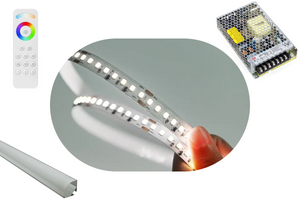

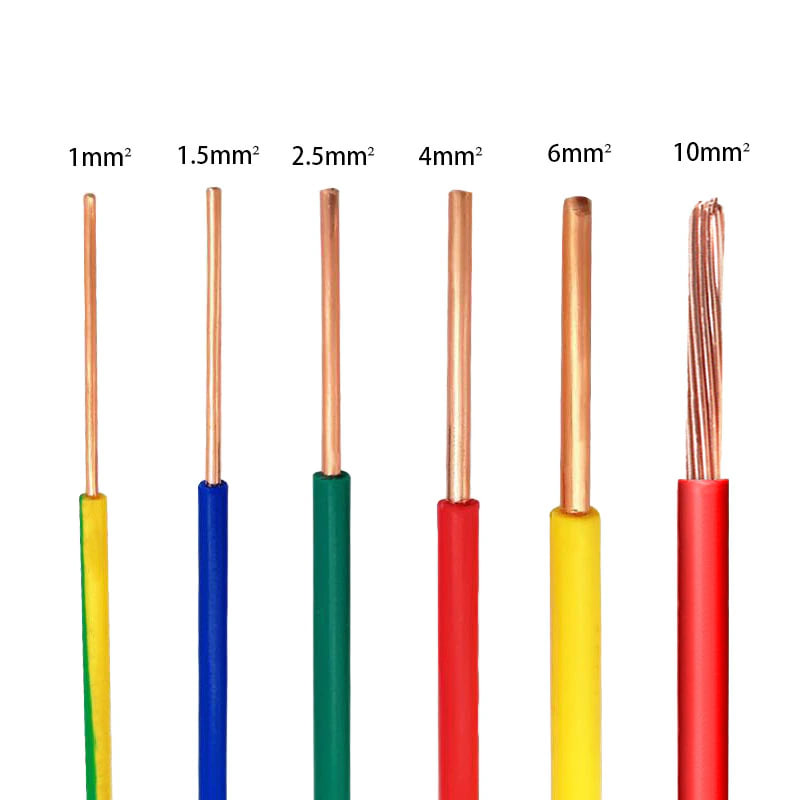

When choosing wires, one of the important factors is their cross-sectional area or wire gauge. This is associated with determining the maximum safe current carrying capacity.

- Using wires that are too thin can lead to their heating up and insulation melting. As a result, fires or short circuits may occur. In domestic electrical systems, such problems often become the cause of fires.

- On the other hand, wires that are too thick will be more expensive, and their length can lead to inefficient expenses. Additionally, when installing LED strips for lighting, it is also important to choose the appropriate cable.

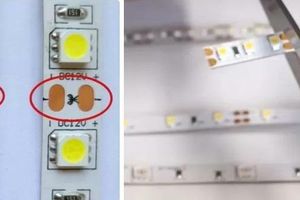

LED strips operate at low voltage but consume a certain current, which must be properly provided by the cable.

Table of wire gauges for connecting LED strips and modules at 12V.

|

Power, W |

Current, A |

Wire diameter, mm |

Section, mm2 |

|

12 |

1 |

0,75 |

0,44 |

|

24 |

2 |

1 |

0,79 |

|

48 |

4 |

1,5 |

1,77 |

|

72 |

6 |

2 |

3,14 |

|

100 |

9 |

2,5 |

4,91 |

So, selecting the correct wire gauge for connecting LED strips is an important aspect. An incorrectly chosen wire can result in energy loss, reduced brightness of the LEDs, or even system failure.

To determine the optimal wire gauge, you need to consider the total power consumption of the LED strips and modules, as well as the distance between the power source and the LED strips. There are standard tables available that help determine the recommended wire gauge based on these parameters.

To learn more about the rules of connecting LED strips and to get additional tips, we invite you to read our article. It provides useful recommendations and highlights common mistakes to avoid when connecting LED strips.

.